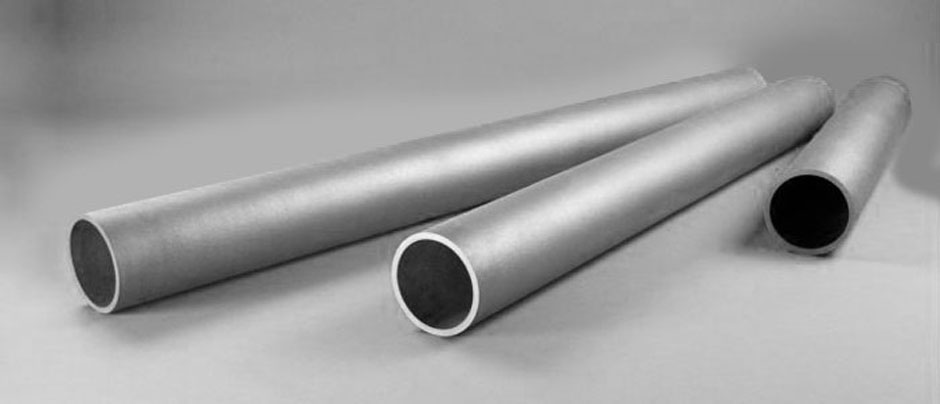

ASTM A312 TP 410 Stainless Steel Seamless Pipe

ASTM A312 TP 410 Stainless Steel Seamless Pipe Manufacturer, Stockholder, Suppliers and Exporter in India,ss 410 pipe manufacturers, ASTM A312 TP 410 Stainless Steel Welded Pipe, a312 tp410 material suppliers

410 Seamless Stainless Steel Pipes & Tube | 410 Stainless Steel ERW Pipes & Tube, 410 stainless steel pipe , stainless steel 410 tube, SS 410 pipe , Astm A358 Tp 410 Stainless Steel Efw Tubes

Call Us for Best Prices for Stainless Steel Pipes, Stainless Steel Tubes and Other Special Alloys!

Buy High Quality Stainless Steel Pipes, SS Tubes! Email Us: sales@shankhmetals.com

Shankh Metals And Alloys Is An ISO: 9001, 14001 & OHSAS: 18001 Certified Company. USLLP Pipes and Tubes keeps up one of the world's biggest inventories of Stainless Steel Pipe (welded and consistent), Fittings, and Flanges for vitality and mechanical applications. L.G. Pipes and Tubes is a family claimed and worked steel pipe fittings and ribs maker. L.G. Pipes and Tubes Supply an assortment of channels and tubes from high review steel. Pipes and tubes are of good quality, long solidness and consumption protection. Distinctive types of Pipes and tubes are consistent, ERW, welded in round and square. Pipes and tubes are made of stainless steel, duplex steel, nickel composite, copper compound, carbon steel or combination steel. Pipes and tubes are accessible in various reaches. We have abnormal state ability and present day advances to produce great pipes and containers of zero deformities. Purchase top notch steel pipe and ASTM A312 TP 410 Stainless Steel Seamless Pipe.USLLP Pipes and Tubes is very much situated to address the issues of an assortment of business sectors.

We are nickel alloy titanium, duplex compound, and stainless steel providers to organizations all through India and in more than 45 nations. L.G. Pipes and Tubes offers an extensive variety of Round Pipes and Tubes, Coil, 'U' Shape tubes, Square pipes and tubes, Rectangular tubes, ASTM A312 TP 410 Stainless Steel Seamless Pipe, 316 Seamless Tubing, 316 Seamless Pipe, ss 316l Seamless Pipe, 304 Seamless Tube, 304 Seamless Stainless Steel Tubing and Hydraulic Tube and so forth. We can meet most ASME, ASTM, AMS, and military particulars, and can cross-reference to most universal benchmarks, including full DIN 3.1b, full 3.1/3.2 Certifcation and NACE necessities.

Contents:

- ASTM A312 TP 410 Stainless Steel Seamless Pipe

- ASTM A312 TP 410 Stainless Steel Seamless Pipe Dimensional Range & specification

- ASTM A312 TP 410 Stainless Steel Seamless Pipe sizes & stock

- ASTM A312 TP 410 Stainless Steel Seamless Pipe price

- ASTM A312 TP 410 Stainless Steel Seamless Pipe manufacturing process

- Dimensions of tubes and pipes

- ASTM A312 TP 410 Stainless Steel Seamless Pipe useful info

- ASTM A312 TP 410 Stainless Steel Seamless Pipe brand manufacturers

ASTM A312 TP 410 Stainless Steel Seamless Pipe Dimensional Range & Standard Specification

Specification:

| Standards | Seamless Pipe |

|---|---|

| ASTM | A 312 |

| ASME | SA 312 |

| Product Name | ASTM A312 TP 410 Stainless Steel Seamless Pipe |

|---|---|

| Range | 6NB to 1200NB – SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS. |

| In Form of | Round, Square, Rectangle, Oval, Coil, Flexible Pipe, Shaft, 'U' Shape, Hydraulic pipe, Honed Tubes |

| In Length of | Standard & Cut length |

| Special Pipes | Fabricated Pipe (with radiography) |

| Value Added Service | Draw & Expansion as per required Size & Length Polish (Electro & Commercial) Heat Treatment Bending Annealed & Pickled Sand Blasting Machining Etc. |

| Material Grade (AISI /TP) | AISI TP 304, TP 304H, TP 304L, TP 304LN, TP 316, TP 316H, TP 316L, TP 316LN, TP TP 316Ti, TP 309, TP 310, TP 317L, TP 321, TP 347, TP 409, TP 410, TP 420, TP 430, TP 446, TP 202 Etc. |

| 0cr18N9, 00Cr19Ni10, 0Cr25Ni20, UNS31803, S31500, S32750, 2205, 904L Nickel Alloy 600, 625, 800, 825, 718 |

|

| TEST CERTIFICATES | MTC, IBR & Third Party Inspection Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

| Specialize | Fabricated Pipe Square & Rectangle & Other Odd Size |

| Specification: | ASTM A 269/A 213/A 312 / EN10216-5 /EN ISO 1127 D4/T3/EN 10305 / PED 97/23 EC |

| Maximum exposure temperature: | 850°C / 1560°F |

Seamless Pipe benefits

1) Pressure Ratings

The greatest advantage of seamless steel pipes is their increased ability to withstand pressure. The weakest point in a welded steel pipe is the welded seam. But because a seamless steel pipe has not been welded, it doesn't have that seam, making it equally strong around the entire circumference of the pipe.

It is also much easier to determine pressure calculations without being required to take weld quality into consideration.

Although seamless pipe can sometimes be more expensive than welded pipe, this increased ability to withstand pressure allows you to use pipes that are thinner and lighter, which can help cut down on expenses.

2) Uniformity of Shape

Because welded seam pipe is wrapped around another form before it is welded, and because welding adds heat, stress and other extraneous variables to the forming process, it can never be as round as seamless steel pipe.

Seamless steel pipe is a continuous extrusion of the alloy, meaning that it will have a round cross section that you can count on, which is helpful when you're installing pipes or adding fittings.

3) Strength Under LoadsSeamless steel pipe can sometimes be more expensive than other forms of steel pipe, but it's also more reliable.

This is because it has greater strength under loading. Empty pipe must always support its own weight, but when a pipe is filled with material–or under load–it must also support that weight as well. Pipe failures and leaks in welded pipes usually occur at the welded seam. But because seamless pipe doesn't have that seam, it isn't subject to those failures.

4) Production Processes

Seamless pipes are manufactured using different procedures, depending on the diameter or the ratio of diameter to wall thickness. The normal raw material is a round spool section preheated in a rotary furnace, or for larger diameters a hollow section preshaped in a perforation press, which is then prerolled in a rotary rolling mill. In the manufacture of longitudinally welded pipes, either individual steel plates or coils are used as raw material. The pipes are produced in a series of different, sequenced process stages, including cold forming, welding, heat treatment, calibration and non-destructive testing.

5) Pipe Lengths and Quantities

When manufacturing seamless pipes, the length manufactured depends on the weight per metre or per rod. Thus up to NB 100, pipe lengths of a maximum 13 m, and up to NB 200 pipe lengths of a maximum of around 4 m can be produced. The minimum purchase quantity is determined by the size of the production batch of around 1 t.