BS 10 FLANGE Suppliers

BS 10 Flanges Supplier, BS 10 Series A and B BS 10 Flanges, Alloy Steel BS 10 Plate Flanges, Carbon Steel BS 10 Flange, Manufacturer of BS 10 Flanges, Nickel Alloy 200 BS 10 Flange, BS 10 Flange Dimensions, MSS SP-44 BS 10 Flanges in Mumbai, India.

Hastelloy C22 BS 10 Flange, Best Price of Duplex Steel BS 10 Flanges, Inconel BS 10 PN40 Flanges, Stockholder Of PN6 BS 10 Flanges, Copper Nickel BS 10 Flanges Exporter, Alloy 20 BS 10 Flanges Traders in India.

Shankh Metals And Alloys Is An ISO: 9001:2008 Certified Company. We are One Of The Leading BS 10 Flanges Manufacturer, Suppliers & Exporter in India. We offer latest technical advancements and carry well maintained inventory ready for immediate delivery to any location. We are supplying flanges in almost everywhere India and also exporting it to countries like UK, Belgium, Saudi Arabia, Dubai, Singapore, Thailand, etc.

BS 10 Flange Manufacturer, Supplies Of BS 10 Flanges, BS 10 Forged Flange, BS 10 Flanges in Forged Steel, Stainless Steel, Carbon Steel C22.8, RST37.2, S235JR, P235GH, P245GH, P250GH, ASTM A105, ASTM A182 F304 (1.4306), F304L(1.4307), F316(1.4404), F316L(1.4404), F321(1.4541) etc.

British Standard BS 10 : 1962 – Specification for Flanges and Bolting for Pipes, Valves, and Fittings. This covers plain, boss, integrally cast or forged, and welding neck type flanges, in ten tables. Although BS 10 is obsolescent, it remains in use for the dimensions of light duty, economy stainless steel flanges in applications where corrosion resistance and/or hygiene, rather than high pressures and temperatures, are the primary considerations. The following tables detail the applicable standard dimensions from Tables D, E, F and H of BS 10.

Stockist of Stainless Steel BS 10 PN6 Flanges, BS 10 Class 150 BS 10 Flange, BS 10 Pipe Flanges, Global Supplier of BS 10 Flanges, ASTM A182 SS BS 10 Flange, BS 10 Plate Flanges Dealer in India, BS 10 Blind Flanges, BS 10 Lapped joint Flanges, BS 10 Threaded Flange, BS 10 Plate Flange Wholesaler.

Table Of Content

Standard Specification For BS 10 Flanges :

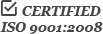

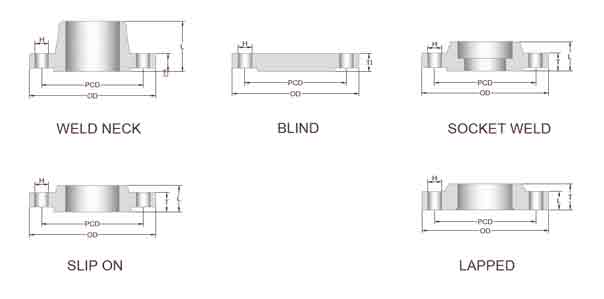

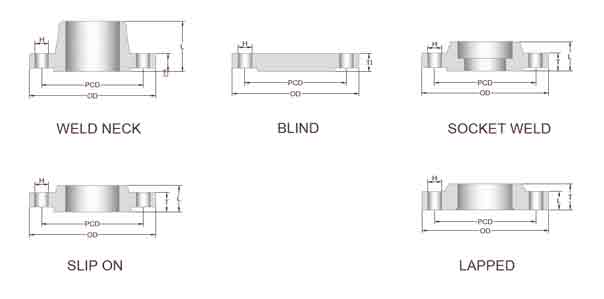

BS flange is a flange system from England, which have flange type including Welding neck Flanges, Plate Slip-on Flanges, Screwed Boss Flanges, Slip on Boss Flanges, slip on flange, blind flange, welded neck flange, threaded flange, lapped joint flange (loose flange), socket welded flange, Orifice Flanges, long weld neck flange and special flangeetc., pressure grade from PN 2.4 to PN 40, Size from 1/2" NB TO 48"NB.

- Type: slip on flange, blind flange, welded neck flange, threaded flange, lapped joint flange(loose flange), socket welded flange, Orifice Flanges, long welded neck flange

- Material: Carbon steel: A105,SS400,SF440 RST37.2,S235JRG2,P250GH,C22.8, Stainless Steel: F304 F304L F316 F316L 316Ti, Copper etc.

- Standard: ANSI,JIS,DIN,BS4504,SABS1123,EN1092-1, UNI,AS2129,GOST-12820

- Size: 1/2-78 inch (DN15-DN2000) / DN15 – DN2000 (1/2″ – 80″), Forged Flange.

- Pressure: ANSI class 150,300,600,1500,2500, DIN PN6,PN10,PN16,PN25,PN40,PN64,PN100,PN160

- Packing: No Fumigate or Fumigate Plywood/Wood Pallet or Case

- Surface Treatment: Anti-rust Oil, Transparent/Yellow/Black Anti-rust Paint,Zinc,Hot dipped Galvanized.

- E-catalogue: Available , please visit catalogue of flange

- Usage: Oil Field, Offshore, Water System, Shipbuilding, Natural Gas, Electric Power, Pipe Projects etc

Manufacturing Standards Of BS 10 Flangess :

Stainless Steel BS 10 Flanges :

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Duplex & Super Duplex Steel BS 10 Flanges :

ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Carbon Steel BS 10 Flanges :

ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706

Low Temperature Carbon Steel BS 10 Flanges : ASTM A350, LF2, LF3

Alloy Steel BS 10 Flanges :

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Copper Alloy Steel BS 10 Flanges : ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

Nickel Alloy BS 10 Flanges :

ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020)

Types Of BS 10 Flanges :

| BS 10 Forged Flanges | BS 10 High Hub Blinds Flanges |

| BS 10 Blind Flanges | BS 10 Spectacle Blinds Flanges |

| BS 10 Reducing Flanges | BS 10 Loose Flanges |

| BS 10 Orifice Flanges | BS 10 RTJ Flanges |

| BS 10 Socket Weld Flanges | BS 10 Screwed Flanges |

| BS 10 Slip On Flanges | BS 10 Weld Neck Flanges |

| BS 10 Flat Flanges | BS 10 Flange Facing Type & Finish |

| BS 10 Lapped Joint Flanges | BS 10 SORF Flanges |

| BS 10 SWRF Flanges | BS 10 Groove & Tongue Flanges |

| BS 10 Square Flanges | BS 10 Long Neck Weld Flanges |

| BS 10 Threaded Flanges | BS 10 Spades Ring Spacers Flanges |

| BS 10 Weld Neck Flanges Series A or B | BS 10 Ring Type Joint Flanges |

| BS 10 WNRF Flanges | BS 10 Weldo / Nipo Flanges |

| BS 10 Expander Flanges |

ANSI B16.5 BS 10 Flange Dimensional Chart

BS 10 Table D Flange Dimensions

Dimensions & Approximate Masses of BS 10 Table D Flange

BRITISH BS 10 TABLE D FLANGE SPECIFICATION

| N.B. SIZE | D | K | L | A | C | N1 | N2 | B | H1 | H2 | R1 | R2 | HOLES | |

| IN | mm | |||||||||||||

| ½” | 15 | 95.3 | 66.8 | 14.5 | 21.3 | 4.8 | 27.0 | 33.3 | 22.4 | 9.5 | 22.2 | 6.4 | 1.6 | 4 |

| ¾” | 20 | 101.6 | 73.2 | 14.5 | 26.7 | 4.8 | 33.3 | 38.1 | 27.7 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1″ | 25 | 114.3 | 82.6 | 14.5 | 33.5 | 4.8 | 42.9 | 47.6 | 34.6 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1 ¼” | 32 | 120.7 | 87.4 | 14.5 | 42.2 | 6.4 | 49.2 | 55.6 | 43.2 | 11.1 | 25.4 | 6.4 | 1.6 | 4 |

| 1 ½” | 40 | 133.4 | 98.6 | 14.5 | 48.3 | 6.4 | 58.7 | 61.9 | 49.5 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2″ | 50 | 152.4 | 114.3 | 17.5 | 60.5 | 7.9 | 69.9 | 74.6 | 62.0 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2 ½” | 65 | 165.1 | 127.0 | 17.5 | 73.2 | 7.9 | 82.6 | 90.5 | 74.7 | 15.9 | 31.8 | 6.4 | 1.6 | 4 |

| 3″ | 80 | 184.2 | 146.1 | 17.5 | 88.9 | 9.7 | 101.6 | 106.4 | 90.7 | 15.9 | 34.9 | 6.4 | 1.6 | 4 |

| 3 ½” | 88 | 203.2 | 165.1 | 17.5 | 101.6 | 9.7 | 114.3 | 119.1 | 103.4 | 17.5 | 34.9 | 6.4 | 1.6 | 4 |

| 4″ | 100 | 215.9 | 177.8 | 17.5 | 114.3 | 9.7 | 130.2 | 133.4 | 116.1 | 19.1 | 41.3 | 9.5 | 3.2 | 4 |

| 5″ | 125 | 254.0 | 209.6 | 17.5 | 141.2 | 12.7 | 152.4 | 160.3 | 143.8 | 19.1 | 44.5 | 9.5 | 3.2 | 8 |

| 6″ | 150 | 279.4 | 235.0 | 17.5 | 168.4 | 12.7 | 184.2 | 185.7 | 171.7 | 19.1 | 47.6 | 9.5 | 3.2 | 8 |

| 8″ | 200 | 336.6 | 292.1 | 17.5 | 219.2 | 12.7 | 241.3 | 241.3 | 221.5 | 22.2 | 50.8 | 9.5 | 3.2 | 8 |

| 10″ | 250 | 406.4 | 355.6 | 22.2 | 273.1 | 16.0 | 292.1 | 298.5 | 276.4 | 27.0 | 63.5 | 9.5 | 3.2 | 8 |

| 12″ | 300 | 457.2 | 406.4 | 22.2 | 323.9 | 19.1 | 342.9 | 349.3 | 325.9 | 28.6 | 69.9 | 9.5 | 4.8 | 12 |

| 14″ | 350 | 527.1 | 469.9 | 25.4 | 355.6 | 22.2 | 406.4 | - | 359.2 | - | 73.0 | 9.5 | 4.8 | 12 |

| 16″ | 400 | 577.9 | 520.7 | 25.4 | 406.4 | 22.2 | - | - | 410.5 | - | - | - | - | 12 |

| 18″ | 450 | 641.4 | 584.2 | 25.4 | 457.2 | 25.4 | - | - | 461.8 | - | - | - | - | 12 |

| 20″ | 500 | 704.9 | 641.4 | 25.4 | 508.0 | 28.6 | - | - | 513.1 | - | - | - | - | 16 |

| 24″ | 600 | 825.5 | 755.7 | 28.7 | 609.6 | 31.8 | - | - | 616.0 | - | - | - | - | 16 |

BS 10 Table E Flange Dimensions

Dimensions & Approximate Masses of BS 10 Table E Flange

BRITISH BS 10 TABLE E FLANGE SPECIFICATION

| N.B. SIZE | D | K | L | A | C | N1 | N2 | B | H1 | H2 | R1 | R2 | HOLES | |

| IN | mm | |||||||||||||

| ½” | 15 | 95.3 | 66.8 | 14.5 | 21.3 | 6.4 | 27.0 | 33.3 | 22.4 | 9.5 | 22.2 | 6.4 | 1.6 | 4 |

| ¾” | 20 | 101.6 | 73.2 | 14.5 | 26.7 | 6.4 | 33.3 | 38.1 | 27.7 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1″ | 25 | 114.3 | 82.6 | 14.5 | 33.5 | 7.2 | 42.9 | 47.6 | 34.6 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1 ¼” | 32 | 120.7 | 87.4 | 14.5 | 42.2 | 7.9 | 49.2 | 55.6 | 43.2 | 11.1 | 25.4 | 6.4 | 1.6 | 4 |

| 1 ½” | 40 | 133.4 | 98.6 | 14.5 | 48.3 | 8.7 | 58.7 | 61.9 | 49.5 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2″ | 50 | 152.4 | 114.3 | 17.5 | 60.5 | 9.5 | 69.9 | 74.6 | 62.0 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2 ½” | 65 | 165.1 | 127.0 | 17.5 | 73.2 | 10.3 | 82.6 | 90.5 | 74.7 | 15.9 | 31.8 | 6.4 | 1.6 | 4 |

| 3″ | 80 | 184.2 | 146.1 | 17.5 | 88.9 | 11.1 | 101.6 | 106.4 | 90.7 | 15.9 | 34.9 | 6.4 | 1.6 | 4 |

| 3 ½” | 88 | 203.2 | 165.1 | 17.5 | 101.6 | 11.9 | 114.3 | 119.1 | 103.4 | 17.5 | 34.9 | 6.4 | 1.6 | 4 |

| 4″ | 100 | 215.9 | 177.8 | 17.5 | 114.3 | 12.7 | 130.2 | 133.4 | 116.1 | 19.1 | 41.3 | 9.5 | 3.2 | 4 |

| 5″ | 125 | 254.0 | 209.6 | 17.5 | 141.2 | 14.3 | 152.4 | 160.3 | 143.8 | 19.1 | 44.5 | 9.5 | 3.2 | 8 |

| 6″ | 150 | 279.4 | 235.0 | 17.5 | 168.4 | 17.5 | 184.2 | 185.7 | 171.7 | 19.1 | 47.6 | 9.5 | 3.2 | 8 |

| 8″ | 200 | 336.6 | 292.1 | 17.5 | 219.2 | 19.1 | 241.3 | 241.3 | 221.5 | 22.2 | 50.8 | 9.5 | 3.2 | 8 |

| 10″ | 250 | 406.4 | 355.6 | 22.2 | 273.1 | 22.2 | 292.1 | 298.5 | 276.4 | 27.0 | 63.5 | 9.5 | 3.2 | 8 |

| 12″ | 300 | 457.2 | 406.4 | 22.2 | 323.9 | 25.4 | 342.9 | 349.3 | 325.9 | 28.6 | 69.9 | 9.5 | 4.8 | 12 |

| 14″ | 350 | 527.1 | 469.9 | 25.4 | 355.6 | 28.6 | 406.4 | - | 359.2 | - | 73.0 | 9.5 | 4.8 | 12 |

| 16″ | 400 | 577.9 | 520.7 | 25.4 | 406.4 | 31.8 | 431.8 | - | 410.5 | - | - | - | - | 12 |

| 18″ | 450 | 641.4 | 584.2 | 25.4 | 457.2 | 34.9 | - | - | 461.8 | - | - | - | - | 12 |

| 20″ | 500 | 704.9 | 641.4 | 25.4 | 508.0 | 38.1 | - | - | 513.1 | - | - | - | - | 16 |

| 24″ | 600 | 825.5 | 755.7 | 28.7 | 609.6 | 47.6 | - | - | 616.0 | - | - | - | - | 16 |

BS 10 Table F Flange Dimensions

Dimensions & Approximate Masses of BS 10 Table F Flange

BRITISH BS 10 TABLE F FLANGE SPECIFICATION

| N.B. SIZE | D | K | L | A | C | N1 | N2 | B | H1 | H2 | R1 | R2 | HOLES | |

| IN | mm | |||||||||||||

| ½” | 15 | 95.3 | 66.8 | 14.5 | 21.3 | 6.4 | 27.0 | 33.3 | 22.4 | 9.5 | 22.2 | 6.4 | 1.6 | 4 |

| ¾” | 20 | 101.6 | 73.2 | 14.5 | 26.7 | 6.4 | 33.3 | 38.1 | 27.7 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1″ | 25 | 114.3 | 82.6 | 14.5 | 33.5 | 7.2 | 42.9 | 47.6 | 34.6 | 11.1 | 22.2 | 6.4 | 1.6 | 4 |

| 1 ¼” | 32 | 120.7 | 87.4 | 14.5 | 42.2 | 7.9 | 49.2 | 55.6 | 43.2 | 11.1 | 25.4 | 6.4 | 1.6 | 4 |

| 1 ½” | 40 | 133.4 | 98.6 | 14.5 | 48.3 | 8.7 | 58.7 | 61.9 | 49.5 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2″ | 50 | 152.4 | 114.3 | 17.5 | 60.5 | 9.5 | 69.9 | 74.6 | 62.0 | 12.7 | 28.6 | 6.4 | 1.6 | 4 |

| 2 ½” | 65 | 165.1 | 127.0 | 17.5 | 73.2 | 10.3 | 82.6 | 90.5 | 74.7 | 15.9 | 31.8 | 6.4 | 1.6 | 4 |

| 3″ | 80 | 184.2 | 146.1 | 17.5 | 88.9 | 11.1 | 101.6 | 106.4 | 90.7 | 15.9 | 34.9 | 6.4 | 1.6 | 4 |

| 3 ½” | 88 | 203.2 | 165.1 | 17.5 | 101.6 | 11.9 | 114.3 | 119.1 | 103.4 | 17.5 | 34.9 | 6.4 | 1.6 | 4 |

| 4″ | 100 | 215.9 | 177.8 | 17.5 | 114.3 | 12.7 | 130.2 | 133.4 | 116.1 | 19.1 | 41.3 | 9.5 | 3.2 | 4 |

| 5″ | 125 | 254.0 | 209.6 | 17.5 | 141.2 | 14.3 | 152.4 | 160.3 | 143.8 | 19.1 | 44.5 | 9.5 | 3.2 | 8 |

| 6″ | 150 | 279.4 | 235.0 | 17.5 | 168.4 | 17.5 | 184.2 | 185.7 | 171.7 | 19.1 | 47.6 | 9.5 | 3.2 | 8 |

| 8″ | 200 | 336.6 | 292.1 | 17.5 | 219.2 | 19.1 | 241.3 | 241.3 | 221.5 | 22.2 | 50.8 | 9.5 | 3.2 | 8 |

| 10″ | 250 | 406.4 | 355.6 | 22.2 | 273.1 | 22.2 | 292.1 | 298.5 | 276.4 | 27.0 | 63.5 | 9.5 | 3.2 | 8 |

| 12″ | 300 | 457.2 | 406.4 | 22.2 | 323.9 | 25.4 | 342.9 | 349.3 | 325.9 | 28.6 | 69.9 | 9.5 | 4.8 | 12 |

| 14″ | 350 | 527.1 | 469.9 | 25.4 | 355.6 | 28.6 | 406.4 | - | 359.2 | - | 73.0 | 9.5 | 4.8 | 12 |

| 16″ | 400 | 577.9 | 520.7 | 25.4 | 406.4 | 31.8 | 431.8 | - | 410.5 | - | - | - | - | 12 |

| 18″ | 450 | 641.4 | 584.2 | 25.4 | 457.2 | 34.9 | - | - | 461.8 | - | - | - | - | 12 |

| 20″ | 500 | 704.9 | 641.4 | 25.4 | 508.0 | 38.1 | - | - | 513.1 | - | - | - | - | 16 |

| 24″ | 600 | 825.5 | 755.7 | 28.7 | 609.6 | 47.6 | - | - | 616.0 | - | - | - | - | 16 |

BS 10 Flanges Application :

|

|