Incoloy ASTM B366 Pipe Bends Supplier

Incoloy DIN 2.4858 Buttweld Bend, Stockist of Incoloy DIN 1.4958 Long Radius Bend, Incoloy Pipe Bend, 800 Incoloy Pipe Bends, 825 Incoloy Piggable Bend Dealer in India, Global Supplier of Incoloy Alloy 925 Hot Induction Bend, ANSI B16.9 Incoloy 800H 3D Pipe Bends in Mumbai, India.

Incoloy UNS N08825 5D Pipe Bend, Best Price of 800HT Incoloy Mitered Pipe Bend Exporter, Stockholder Of Incoloy 800 10D Pipe Bend, Incoloy Bend, ASME S366M Incoloy 825 Customized Pipe Bend Wholesaler, Incoloy 800H Bend, Incoloy UNS N09925 45 Deg. Pipe Bend Traders in India.

Shankh Metals And Alloys Is An ISO: 9001:2008 Certified Company.We Manufacturer Our Products By High Grade Material To Provide Good Quality Incoloy Pipe Bends To Our Domestic And Overseas Customers. Bends accomplish a Lot of admiration by our clients owing to its high strength, dimensional correctness, high tension power, corrosion resistant and consistency products like Incoloy 800 3D Pipe Bend, Incoloy UNS N08800 Hot Induction Bends & Incoloy 825 ASTM B366 Pigabble Bends. These products are used in various commercial, industrial and automobile industries. We manufacture UNS N08810 Nickel U-Pipe Bends using high grade of raw material by implementing most ultra modern technology. These products are clients can avail from us at various sizes, shapes and design as per the requirements.We are one of the top Manufacturers and Suppliers of WNR 2.4858 Incoloy Seamless Pipe Bends. We Manufacture Other range of ASTM B366 Incoloy 800 Pipe Bends such as Incoloy 800H Long Radius Bend, Incoloy 825 Piggable Bend, 925 Incoloy Hot Induction Bend, 800HT Incoloy Seamless Pipe Bend, Alloy 825 Welded Pipe Bend, Incoloy 800 U Pipe Bend, Incoloy 925 J Pipe Bend, Incoloy 800H Mitered Pipe Bend, Incoloy 800 3D Pipe Bend in Mumbai, India.

ANSI B16.9, ANSI B16.28, MSS SP-43, or MSS SP-75 Incoloy Pipe Bends, Werkstoff No 1.4876 Incoloy High Pressure Bending, 800 Incoloy Welded Pipe Bend, Incoloy ASTM B366 UNS N08800 Seamless Pipe Bend, 825 Incoloy U Pipe Bend, Manufacturer Of ASTM B366 925 Incoloy J Pipe Bend.

Table Of Content

- Standard Specification For Incoloy Pipe Bend

- Manufacturing Standards Of Incoloy Pipe Bends

- Incoloy Incoloy Bend Equivalent Grades

- Types Of Incoloy Pipe Bends

- ASTM B366 Incoloy Long Radius Bend

- ASTM B366 Incoloy Piggable Bend

- ASTM B366 Incoloy Hot Induction Bend

- ASTM B366 Incoloy Seamless Pipe Bend

- ASTM B366 Incoloy Welded Pipe Bend

- ASTM B366 Incoloy U Pipe Bend

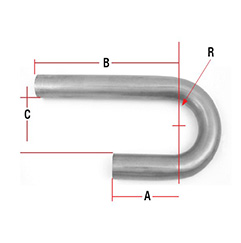

- ASTM B366 Incoloy J Pipe Bend

- ASTM B366 Incoloy Mitered Pipe Bend

- ASTM B366 Incoloy 3D Pipe Bend

- ASTM B366 Incoloy 5D Pipe Bend

- ASTM B366 Incoloy 10D Pipe Bend

- Chemical Composition of Grade Incoloy Pipe Bends

- Mechanical Properties of Incoloy Pipe Bends

- Price List Of Incoloy Pipe Bend

- Incoloy Pipe Bend Available Types

- Incoloy Pipe Bend Application

- Export Destinations For Incoloy Pipe Bend

Standard Specification Of Incoloy Pipe Bend :

Specifications : ASTM B366 & ASME SB366

Dimensions : ASME/ANSI B16.9 B16.28 and MSS SP-43 SP-75

Size : Seamless Pipe Bends (1/2″ – 24″), ERW Welded Fabricated Pipe Bends (2″ – 36″)

Outer Diameter : 38.0 mm – 206.0 mm

Wall Thickness : 1.5 mm 2.0 mm 3.0 mm – greater wall thickness at request

Bend Radii : 75 100 150 250 300 500 800 1,000 1,200 1,500 mm

Bending Radius(R): R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom

Bending angle (θ): 15°, 30°, 45°, 60°, 90°, 135°, 180°

Grades : Incoloy 800, 800H, 800HT, 825, 925 Pipe Bends

Manufacturing Standards Of Incoloy Pipe Bends :

| ASME Pipe Bend | ANSI B16.9, ANSI B16.28, MSS-SP-43 |

| DIN Pipe Bend | DIN2605, DIN2615, DIN2616, DIN2617, DIN28011 |

| EN Pipe Bend | EN10253-1, EN10253-2 |

| ASTM B366 | ASME SB366 – Standard Specification for Wrought Austenitic Incoloy Piping Fittings |

| ASME B16.9 | Factory-Made Wrought Fittings Buttwelding |

| ASME B16.25 | Buttwelding Ends ASME B16.28 – Wrought Steel Short Radius Elbows and Buttwelding Returns |

| MSS SP-43 | Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion Resistant Applications |

Types Of Grade Incoloy Pipe Bends

ASME SB366 Incoloy Bend Equivalent Grades :

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN | OR |

| Incoloy 800 | 1.4876 | N08800 | NCF 800 | NA 15 | ЭИ670 | Z8NC32-21 | X10NiCrAlTi32-20 | XH32T |

| Incoloy 800H | 1.4958 / 1.4876 | N08810 | NCF 800H | NA 15(H) | ЭИ670 | Z8NC33-21 | X5NiCrAlTi31-20 | XH32T |

| Incoloy 800HT | 1.4859 / 1.4876 | N08811 | NCF 800HT | NA 15(HT) | ЭИ670 | - | X8NiCrAlTi32-21 | XH32T |

| Incoloy 825 | 2.4858 | N08825 | NCF 825 | NA 16 | ЭП703 | NFE30C20DUM | NiCr21Mo | XH38BT |

Chemical Composition of Grade Incoloy Pipe Bends :

| Grade | C | Mn | Si | S | Cu | Fe | Ni | Cr | Al | Ti |

| 800 | 0.10 max | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800H | 0.05 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60 | 0.15 – 0.60 |

| 800HT | 0.06 – 0.10 | 1.50 max | 1.00 max | 0.015 max | 0.75 max | 39.50 min | 30.00 – 35.00 | 19.00 – 23.00 | 0.15 – 0.60ᴬ | 0.15 – 0.60 |

| 825 | 0.05 max | 1.00 max | 0.5 max | 0.03 max | 1.50 – 3.00 | 22.00 min | 38.00 – 46.00 | 19.50 – 23.50 | 0.02 max | 0.06 – 1.20 |

Mechanical Properties of Incoloy Pipe Bend :

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 800 / 800H / 800HT | 7.94 g/cm3 | 1385 °C (2525 °F) | Psi – 75,000 , MPa – 520 | Psi – 30,000 , MPa – 205 | 30 % |

| 825 | 8.14 g/cm3 | 1400 °C (2550 °F) | Psi – 80,000 , MPa – 550 | Psi – 32,000 , MPa – 220 | 30 % |

Incoloy Pipe Bend Available Types :

| Incoloy 800 Pipe Bend | Incoloy 825 Buttweld Bend |

| Incoloy 800HT Mandrel Bends | Incoloy 800H Long Radius Bend |

| Incoloy UNS N08800 Piggable Bend | Alloy 925 Hot Induction Bend |

| Incoloy UNS N08810 Seamless Pipe Bend Suppliers | ANSI 825 Welded Pipe Bend |

| 925 Incoloy U Pipe Bend Dealer | Alloy 800 J Pipe Bend Exporter |

| Incoloy 800HT Mitered Pipe Bend Stockholder | Incoloy UNS N08825 3D Pipe Bend Distributors |

| Incoloy UNS N08811 5D Pipe Bend | Alloy 600 10D Pipe Bend Manufacturer |

| Incoloy DIN 1.4876 2.5D Pipe Bend | Incoloy DIN 1.4958 22D Pipe Bend |

| Incoloy 800 Customized Pipe Bend | DIN 2.4858 Incoloy Bend |

| ANSI B16.9 Incoloy UNS N09925 12D Pipe Bending | Incoloy 800H High Pressure Bending Stockist |

| ASTM B366 Incoloy 800 180 Degree Pipe Bend | ASME SB366 Incoloy 825 DIN Pipe Bend |

| Incoloy 925 EN Pipe Bend | 800HT Alloy ASME Pipe Bend |

| Incoloy DIN 1.4959 Small Size Pipe Bending | ASME SB366M Incoloy 800 Pipe Bend Elbow |

| Incoloy 800 90 Degree Pipe Bend | 800HT Incoloy 160 Deg Pipe Bend |

Incoloy Pipe Bend Price List

- Incoloy 10D pipe bend, Incoloy bended steel pipe, Incoloy bended steel tube

FOB Price in India : US $50-10000 Piece - Incoloy 3D hot bender for pipe tube bending

FOB Price in India : US $50-10000 Piece - best price Of Incoloy Pipe Bends Elbow

FOB Price in India : US $10-1000 Piece - Incoloy Long radius hot bend pipes

FOB Price in India : US $0.06-0.39 Ton - Incoloy pipe bend

FOB Price in India : US $0.2-526 Piece

Incoloy Pipe Bend Application

- Industrial Boilers

- Power Plants

- Nuclear Plants

- Oil & Gas Industry

- Refineries

- Ship Building

- Heat Exchangers

- Condensers

- Paper & Pulp

- Marine Applications

- Nuclear Power

- Fossil Fuel Power Plants